The hoses in the cooling system in your vehicles are connected and sealed with hose clamps. Spring and screw are two of the most common hose clamp types. If you need to change the hose clamps, you might get confused about which one is better. When deciding between spring hose clamps vs. screw hose clamps, experts prefer spring.

The major difference between a spring and a screw hose clamp is the amount of tension or pressure they put on the hose. Spring hose clamps put constant and firm tension. Screw clamp hoses are tightened with screws, and the inner diameter remains the same. In consequence, pressure is inconsistent on the hoses.

Is it enough to decide which one to use in your vehicle? Obviously not. There are some other differences that will help you to understand which one is better and why. Stay tuned till the end to know everything about spring and screw hose clamps and their differences.

Hose Clamps: The Basics

The main purpose of using hose clamps is to prevent leakage in the cooling system. Regardless of what type of vehicle you use, there should be multiple hose clamps. They come in various types. But most people use either spring hose clamps or screw hose clamps.

See More: Nylon vs Stainless Braided Hose

What is a Spring Hose Clamp?

Spring hose clamps, also known as constant tension hose clamps, are made of spring steel. They are cut in such a way that the connector at one end has an extension in the center, while the other end has extensions on each side. The design can be a little different, but the connector will always act as a spring.

If you ask how to use spring hose clamps, the answer is simple. First, press the tabs to enlarge the clamp. Then place the clamp on the hose and release the tabs. The spring hose clamp will create suitable tension on the hose.

What I like:

- The spring component helps to keep the pressure constant.

- It continues to put pressure as long as the hose is okay.

- It stays in good condition for a long period.

What I don’t like:

- It can not be used to create high pressure.

Video: How To Spring Hose Clamps Setting

What is a Screw Hose Clamp?

Screw hose clamps, also known as worm gear clamps, are ring-shaped metal clamps that use screws as connectors. You can change the diameter as you want by turning the screw. The diameter will remain fixed as long as the clamp is in good condition or unless you change it.

But how to use a screw hose clamp? First, place it around the hose you want to seal. And then start tightening the screw to secure the hose. Do not try to overtighten as that can damage the hose or the screw.

What I like:

- The diameter remains the same, which can be good in certain situations.

- You can fix or change the diameter as you want.

What I don’t like:

- The screw can get loose over time.

- The fixed diameter of screw hose clamps can cut through and damage the hose.

Check Also: Silicone vs Rubber Vacuum Hose

spring hose clamps vs screw: Key Differences

Spring and screw hose clamps are two completely different types of clamps. Though the purpose is similar, their distinguishable features make one better than the other in certain situations.

Some of the common differences between spring hose clamps and screw hose clamps are:

- Pressure/Tension

The amount of pressure they use is a major difference that separates these two clamps. A spring hose clamp uses spring material; therefore, it can stretch or shrink with the hose. So, it keeps putting even pressure on whether the hose is dry out or enlarged.

In contrast, the diameter of a screw is fixed. So, when the hose is dried out, the pressure is low, and when the hose is enlarged, the pressure is strong.

- Flexibility

As spring material can stretch or shrink when necessary, spring hose clamps are quite flexible with hoses. But screw hose clamps can not do that. As a result, when the hose is enlarged, screw hose clamps can cut into the hose pipe and damage it.

- Design

The design of the two clamps is also different. Another reason why screw hose clamps can cut through the rubber hose pipe is their sharp edges. Spring hose clamps designs do not have such sharp edges and are safer to use.

- Durability

Both of the clamps have pretty good durability. They can serve you the lifetime of your car. However, in certain situations, the screw of the worm gear hose clamps can get loose.

Then it will make the hose insecure, and you may need to change the clamps. Spring hose clamps do not have such problems.

- Diameter

You can adjust the diameter of screw hose clamps within a certain range. But you do not get that benefit with spring hose clamps. So, when you need clamps with a specific diameter, screws are an obvious choice.

- Compatibility

Spring hose clamps are compatible with both small and large diameters of hoses. Screw hose clamps are mainly used in hoses with a larger diameter, usually ½ inch and higher.

Spring hose clamps vs screw: Quick Comparison Chart

| Basis of Comparison | Spring Hose Clamps | Screw Hose Clamps |

| Pressure | Constant | Unstable |

| Flexibility | Flexible | Fixed |

| Durability | Excellent | Above average |

| Design | Smooth inside and edges | Sharp edges |

| Diameter | Changes naturally | Manually adjustable |

| Compatibility | All sizes | For hose above ½ inch |

| Material | Spring steel | Stainless steel |

| Price | $0.10-$0.20 per piece | $0.15-$35 per piece |

Which One Should You Buy?

After knowing the differences, you can easily decide which one you should buy. However, our recommendation would be to go for spring hose clamps considering the benefits they offer over screw hose clamps. You also can go for the screws if you need the benefit of adjusting the diameter.

Best Spring Hose Clamps

Hilitchi Spring Band Type Action Fuel/Silicone Vacuum Hose Pipe Clamp

Hitachi spring vacuum hose pipe clamp is made of high-quality carbon steel for high durability. Besides, the zinc plating helps to avoid corrosion and rust. These automotive spring hose clamps can be used for different purposes.

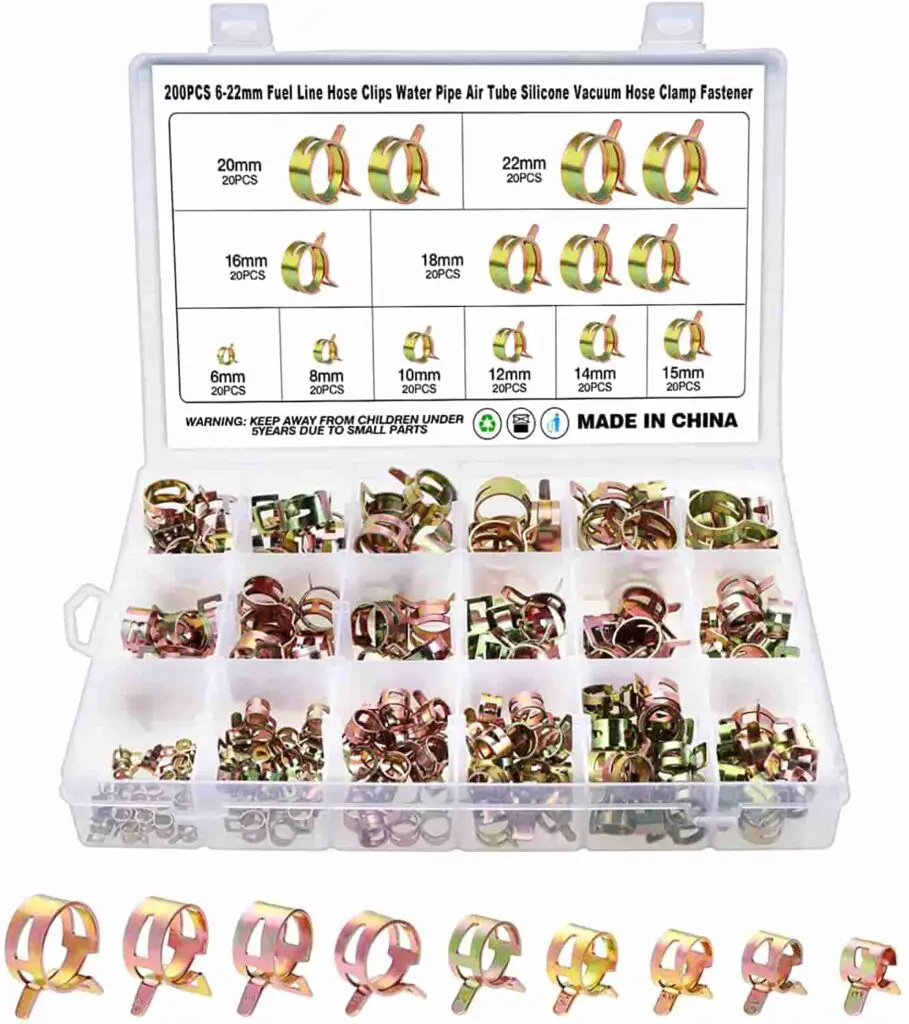

OCR 6-22mm Fuel Hose Line Spring Clip Clamps Fasteners Silicone Vacuum Hose Pipe Clamp

You also can go for the OCR Hose Line Spring Clip Silicone Vacuum Hose Pipe Clamp. These are made of 65Mn spring steel to maintain their high quality. The smooth inside design ensures that it does not bite into the hose pipe. The 360-degree inner ring design helps in preventing damage to pipes efficiently. It is also quite sturdy and easy to use.

Best Screw Hose Clamps

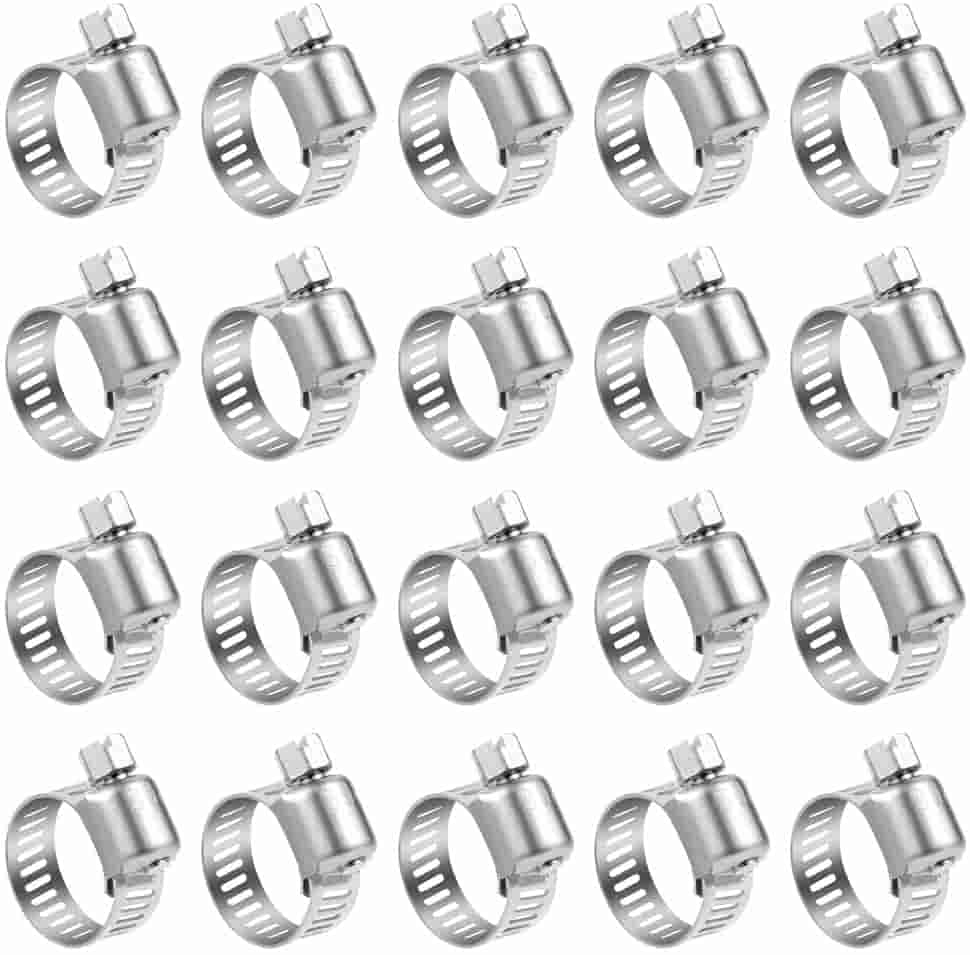

Glarks Adjustable 8-44mm Range 304 Stainless Steel Worm Gear Hose Clamps

Glarks stainless steel worm gear hose clamps are made of 304 stainless steel to ensure high-quality performance and excellent durability. The material is also corrosion and acid-resistant. You can easily install the clamps and also can adjust the size as necessary within the given range.

Hose Clamp, Stainless Steel Adjustable 6-12mm Size Range Worm Gear Hose Clamp

You also can go for Stainless Steel Adjustable 6-12mm Size Range Worm Gear Hose Clamp from Lok Man. The materials are of good quality and waterproof, and corrosion-proof. You can use these in automotive and other mechanical works. These are recyclable too.

Conclusion

The comparison between spring hose clamps vs. screw hose clamps shows why experts prefer the former. You can buy the one that suits your needs. In short, spring hose clamps are a safer option due to their constant tension and smooth design. The price is also low. But you can adjust the diameter of screw hose clamps as per your preference.