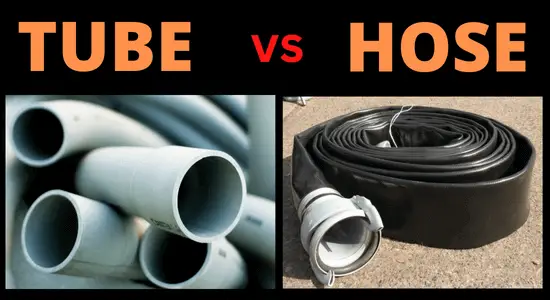

Ever went to the shop to buy a hose and ended up getting a tube in return? It happens to most of us. Tubes and hose are two different tubular forms often confused as one and thus used synonymously. But there exists some major difference between the two.

The hose is reinforced tubular, which we can count as a Jack of all trades, while a tube isn’t. It can be used for limited purposes only. However, they are considered a better option than pipes.

Yearning to learn tube vs. hose- the difference, and which one is better? Then keep your calm and stick with us till the end, as this article covers all the nitty-gritty about it!

What is A Hose?

A hose is a long cylinder pipe used to transfer simple as well as high-pressurized fluids from one place to another with minimum chances of leakage. They are highly flexible and thus can be used to carry high pressurized and compressed gasses and liquids.

What is A Tube?

A tube is a long hollow cross-section that carries fluids, heat, and low-pressure gas. They come in several shapes and sizes and are mostly made of aluminum, steel, or carbon alloy. It is sturdy yet flexible, making it ideal for various household applications.

Read More: Pipe vs Tube

Tube vs. Hose – A Head-on-Head Comparison!

Now that you are well abreast with the rudiments and basics of both tube and hose, let’s go through their detailed comparison and figure out what makes one better than the other.

- Tube vs. Hose Sizing and Measurement

The first and prime difference between tube and hose is their sizing process. The tube is measured in inches with respect to the outer diameter and wall thickness.

However, the inner diameter is measured and leveraged for the hose according to the dashed scale. In this system, you express the inner diameter in 1/16 inches.

- Tube vs. Hose Manufacturing Process

The manufacturing processes of tubes and hoses are very different. In tubes, you pass them from rollers, followed by treating them with a welding machine to qualify the hard rules of inspections, including hot phase, cold drawing, and finishing.

However, in the manufacturing process of the hose, you pass the material through a set of rollers to make it smooth, followed by cutting them into thin strips of the required thickness. Later, they are hammered into the required shape on a steel mandrel and covered with reinforcements.

- Tube vs. Hose Applications

Hose and tubes are used in many industries, including the hydraulic, pharmaceutical, cryogenic, fuels, oil and gas industries, etc. Moreover, both are used to transfer fluids, gas, and heat exchanges.

But the only difference is that the tube is limited to carrying fluids with low pressure built up, but the same isn’t true for a hose. It can be used for both extremely high-pressure applications as well as random ones. That is why it is claimed to be the master of all trades.

- Tube vs. Hose Heat Absorbing Power

When considering heat absorbing and reflecting power, the tube manages to get the crown. Tubes are painted with a layer of reflective coating to reflect off the heat instead of absorbing it.

So, they can easily handle temperatures as high as 400 degree Celsius before cracking. However, a hose allows the heat to pass through and can handle up to 100-degree celsius.

- Tube vs. Hose Flexibility

The hose is created from soft material and thus is more flexible than the tube. Moreover, it has a large bent radius, allowing a faster fluid flow with minimal resistance. However, the tube offers a lot of flow resistance.

- Tube vs. Hose Reinforcements

Hoses are usually reinforced so that they can be used in situations of high-pressure levels. These reinforcements include metal mesh, embedded braids, dual walls, etc.

But on the other hand, tubes have no such reinforcements.

- Tube vs. Hose Materials

A hose is mainly made of soft materials like nylon, polyurethane, polyethylene, rubber, etc. On the other hand, a tube is made of steel, aluminum, brass, copper, or paperboard.

- Tube vs. Hose LifeSpan

Since tubes are resistant to factors like heat, abrasion, radiation, vibrations, and exposure to chemicals, it has a longer lifespan than a hose.

Unfortunately, a hose is likely to suffer from abrasive and frictional environments despite being covered with covers and sleeved.

- Tube vs. Hose UV Light Resistance

Since a hose is made of materials like rubber and nylon, it can’t withstand UV radiation for a longer time and thus breaks down with time. However, tubes are made of UV radiation-resistant materials like steel and copper.

Pros and Cons Of Tube vs Hose

The pros and cons of tube and hose are:

Pros of Tube:

- Much lightweight than the hose

- Conduct electricity

- Longer lifespan

- It doesn’t expand on exposure to high temperature

Cons of Tube:

- Not longer than 20 inches

- Hard to install

- Easily gets corroded

Pros of Hose:

- Comparatively more flexible that allows them to be used for various purposes

- Have a large bent radius

- Easy to fabricate

Cons of Hose:

- Heavier than tube

- Are not able to dissipate heat

- Not good conductors of heat

- Can’t be exposed to high temperature

Frequently Asked Questions About Hose vs Tube

Q.1 How to measure a hose?

To measure a hose or know the size of a hose, always wrap a thread on its inner side to get the circumference. Then divide it by 3.142 to get the diameter. Always use the inner diameter to measure the hose, not the outer diameter.

Q.2 What is the role of a hose in a car?

A hose is used in cars to absorb vibrations between the radiators and the engine. It is usually made of rubber compounds.

Q.3 Is a tube better than a hose?

Neither of the two can be claimed as better than the other. If you want the conveyance of compressed gas or high-pressure levels, the hose will work best for you. However, the tube is better if you want a longer lifespan tubular to carry fluids and glasses.

Q.4 What is a sprinkler hose?

A sprinkler hose is a special type of hose with perforated ends to sprinkle fluids at a distance of 10 feet.

Conclusion

To sum up the discussion, one can say that both hoses and tubes are equally important tubulars, each having its own function to perform.

We can’t use them interchangeably. Where a hose helps us carry fluids with the least flow resistance or friction, a tube works for a longer time and offers heat resistance.